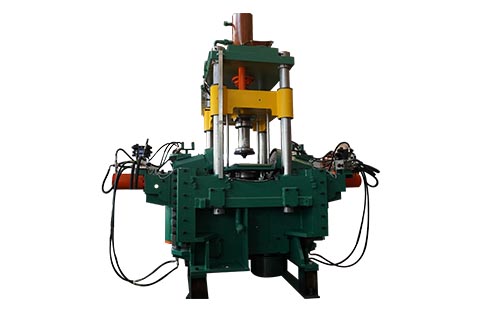

spinning machine

XYJ-600 spinning machine, consisting of a vertical welded structure

Its main components are as follows:

1、 Bed accessories; 2、 Spindle unit assembly; 3、 Upper Top Cylinder Assembly; 4、 Rotary wheel assembly

5、 Hydraulic system; 6、 Lubrication system& nbsp; & nbsp; & nbsp; 7、 Electrical System& nbsp; 8、 Cooling system

| 22383;-radius range | 405mm-≤ 8709; 690mm |

| A thick range of 22383; | 8mm-18mm |

| Iraqi 22791; high | 150 mm |

| It's about 31961 degrees. | 3.2-1.6 |

| 36724; PZ to the greatest force | 35KN (35x121544444) |

| Radius to the most powerful Pr | 370KN(37x12154444) |

| The conclusion of the EEA | 180KW |

| Thirty-six thousand; Thirty-six thousand; Thirty-six thousand; Thirty-eight thousand; | 340mm |

| Radius up to 32568;, activated 26438;, sequence nbsp; | 260mm |

| Every spring 32568;'s speed range | 50-300mm/min |

| Each range of 32568;'speed range ' | 1200-1800mm/min |

| mainly 36724; speed | 150-200rad/min |

| The size of the main desktops. | 4000mmX1650mmX3700mm(长X 宽X高) |

| Thieves 22791s; | 27T |

| Congratulations. | 50 seconds. |

characteristic

1. The bed, main shaft, transmission system, and wheel seat of the spinning machine have sufficient stiffness

2. The lateral and longitudinal feeding mechanism of the rotary wheel seat adopts a hydraulic system (anti type valve - Taiwan Oil Research), and the product is spun out through the anti type plate to generate sufficient spinning pressure to meet the process requirements.

3. Ordinary spinning machines often use one spinning wheel, but in order to balance the radial force during spinning, reduce the bending deflection, deflection, and vibration of the main shaft and mold core, there are usually multiple auxiliary forming wheels, which are symmetrically configured relative to the main axis. At the same time, the transverse and longitudinal feed of the spinning wheel is controlled by hydraulic pressure, which is also to improve the accuracy of its spinning parts.

4. The spindle has sufficient transmission torque and power to ensure rotational pressure.

5. The main shaft adopts heavy-duty rolling bearings to withstand the large working force generated by the spinning wheel and tailstock cylinder during spinning, and provides good cooling and lubrication for the main shaft and its bearings.

6. The upper oil cylinder generates sufficient tightening force on the clamping block to ensure the clamping of the blank during work, while also helping to improve the stiffness requirements of the rotating parts such as the spindle wheel.

© 2018 Shandong Xiaoya Jinggong Machinery Co., Ltd.|Lu ICP 11005049-1

Sweep Learn more

Sweep Learn more

Address:No. 51, Industrial South Road, Jinan City, Shandong Province

International Trade Department:+86 0531-83122188

E-mail:xiaoyatooling@163.com

+86 400-6586-222

+86 400-6586-222